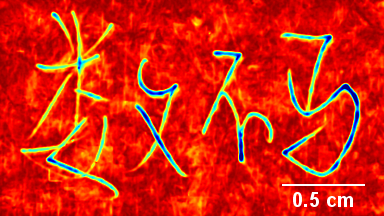

Roughness quality control

Hip prosthesis roughness

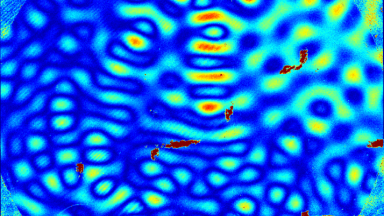

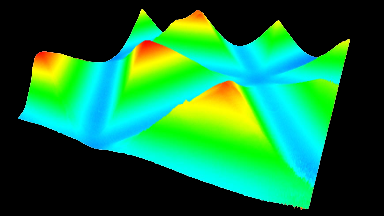

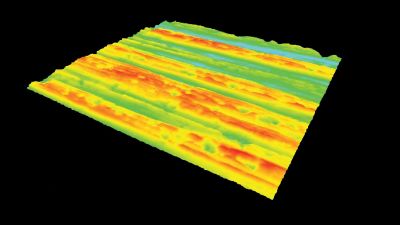

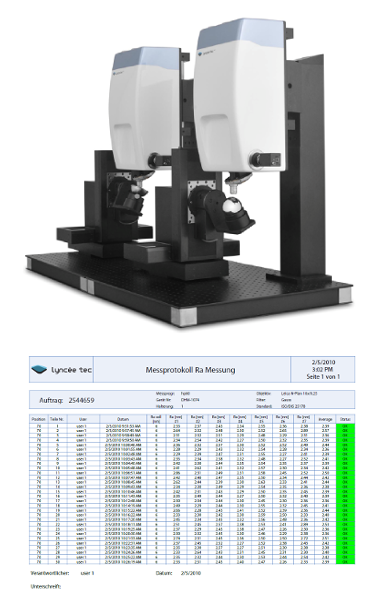

Medical Authorities requires roughness measurement according to ISO Standard for human implementation of hip prosthesis. Lyncée Tec has developed a system for their automated measurement with manual loading of both cup and ball hip spherical prosthesis:. It enables:

- Measurement in production environment with external vibrations due to surrounding presence of CNC and polish machines

- Quality control of roughness with very low Ra acceptance threshold

- Implant diameters form 1cm to 8cm

- Non-contact measurement to avoid any scratch and surface contamination

Successful comparison of DHM measurements has been carried out on hip prosthesis characterized by METAS (The Swiss Federal Institute of Metrology).

Description

- Material:

- Stainless steel hip prostheses

- Diameter from 1 cm to 8 cm

- Typical Ra threshold: 1 to 6 nm

- Automated Process

- Manual prosthesis loading

- Bar code reading for lot authentication

- Automation of cap and ball orientation according to dimension

- Automated focalization

- Scan of the surface

- Automated report on the lot on a secure server

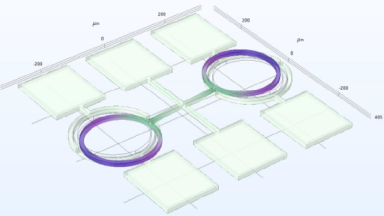

- Instrument:

- DHM® R-1000

- Stage with 5 motorized axis: XYZ, θ, ϕ

- Software

- TCP/IP remote to control a network of 3 DHM® by an automated supervision system for acquisition and data management

- Customized user interface dedicated to the application and adapted to production operators

- Time scale for the full process: <30 s

- Magnification: 10x

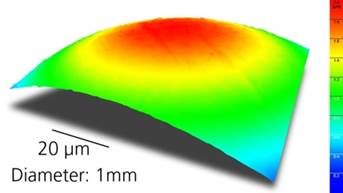

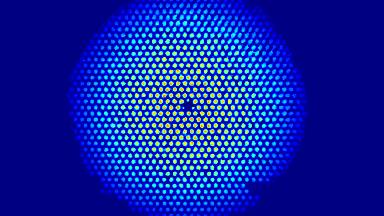

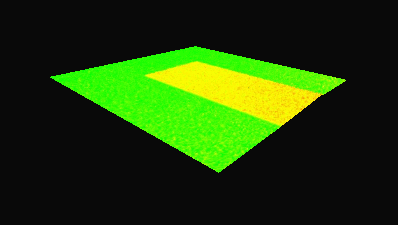

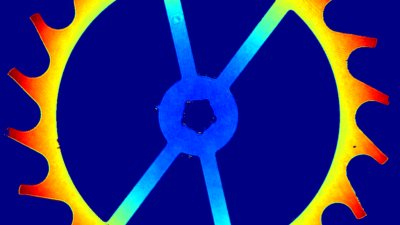

Bearing Ball roughness

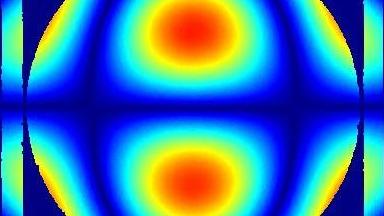

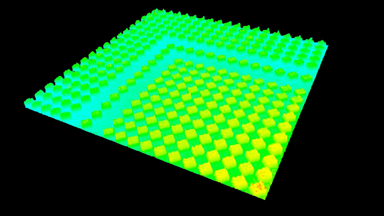

Bearing balls roughness influences wear behavior, especially when made out of ceramics. DHM® are capable of characterizing them very efficiently:

- DHM® provide full field of view measurement instantaneously, without any scanning. It enables on-flight measurements, without stopping the ball rotation.

- Use of Ultra High Numerical aperture objective enables to measure balls of small radius.

- Infinite depth of focus provides a sharp focus over the whole surface thanks to digital focusing.

Descripion

- Material:

- Stainless steel and ceramic balls

- Diameter down to 0.4 mm

- Typical Ra threshold: 10 nm

- Automated Process

- Ball rotation

- Automated OK/NOK decision

- Instrument:

- DHM® R-1000

- Software: customized user interface realized using the Software Development Kit

- Time scale for the full process: <10 s

- Magnification: 10x or 20x