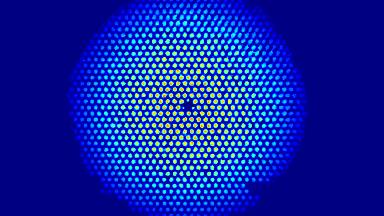

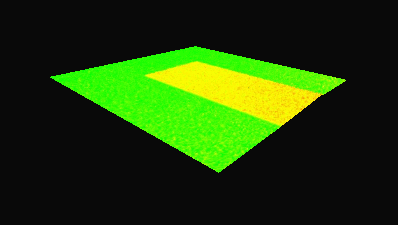

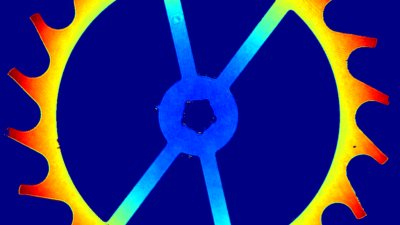

Smart Polymer

“Smart surface coating”

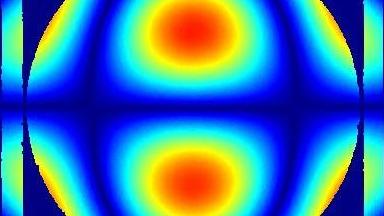

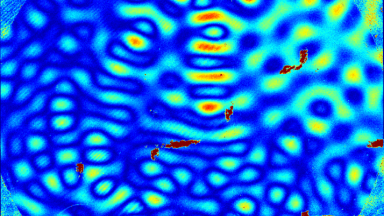

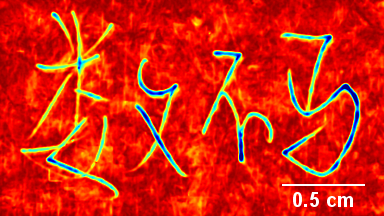

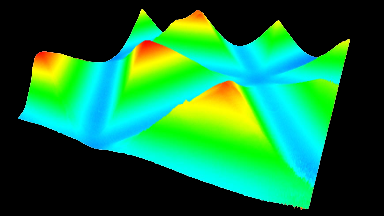

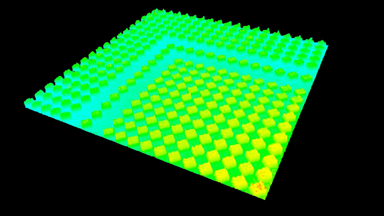

“Smart coating surface” is basically photoactivated generation of disorder in a liquid crystal network which produces free volume that leads to the controlled formation of dynamic corrugations at its surface. The liquid crystal order amplifies the deformation of copolymerized azobenzene, which takes place on molecular length scales, to a micrometer-sized macroscopic phenomenon based on changes in density. In another word, this phenomenon enables “smart coating surface” to switch between flat and pre-designed corrugated states by external trigger (e.g. dual wavelength excitation, electric field, or temperature variation) at the frequency ranging from 1 to 100 Hertz.

Description:

- Courtesy of : Eindhoven University of Technology, The Netherlands & Kent State University, USA

- Material: Liquid crystal elastomer

- Instrument: DHM® R-2200

- External stimulus: Light, temperature, electrical field

- Time scale: Between ms and minutes

- Magnification: 40x

Publications:

1. New insights into photoactivated volume generation boost surface morphing in liquid crystal coatings, Danquing Liu & Dirk J.Broer, Nature Communications 6, Article number: 8334 (2015) doi:10.1038/ncomms9334

2. Protruding organic surfaces triggered by in-plane electric fields, Danqing Liu, Nicholas B. Tito & Dirk J. Broer, Nature Communications 8, Article number: 1526 (2017) doi:10.1038/s41467-017-01448-w

3. Oscillating Chiral‐Nematic Fingerprints Wipe Away Dust, Wei Feng, Dirk J. Broer & Danqing Liu, Advanced Materials 2018, 30 , 1704970, DOI: 10.1002/adma.201704970

4. Liquid crystal elastomer coatings with programmed response of surface profile, Greta Babakhanova, Taras Turiv, Yubing Guo, Matthew Hendrikx, Qi-Huo Wei, Albert P.H.J. Schenning, Dirk J. Broer & Oleg D. Lavrentovich, Nature Communications 9, Article number: 456(2018), DOI:10.1038/s41467-018-02895-9

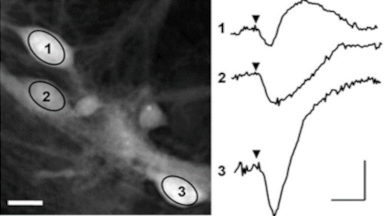

Self-healing polymer

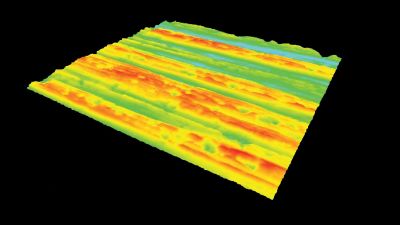

The surface is scratched by a metallic tool. The DHM® records the surface recovery through time.

The animation above represents both 4D topography and dynamic profile.

Description:

- Courtesy of : Tosoh Corporation

- Material: Self recovering polymer

- Instrument: DHM® R-1000

- Time scale: <5 mintues

- Magnification: 10x