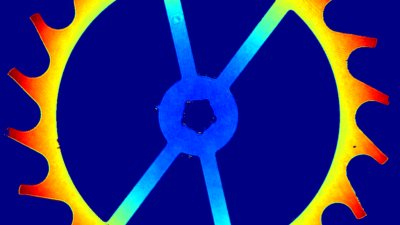

MEMS Actuator

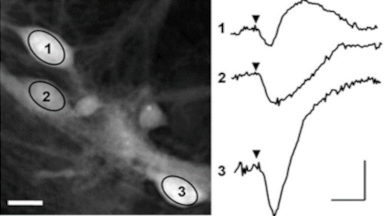

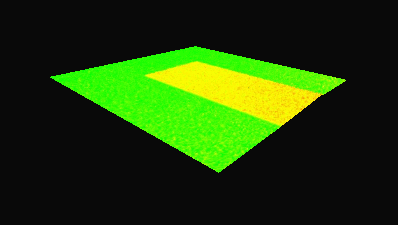

Device with “large” in-plane displacement

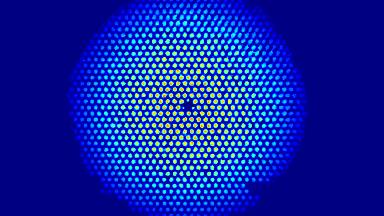

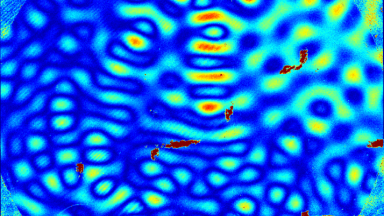

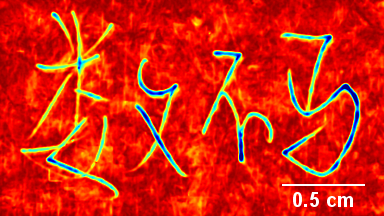

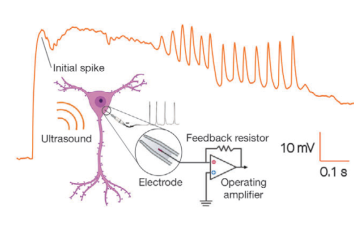

Micromotor are used in micro-scale surgery, assembly, propulsion, and actuation among others. To provide large displacements, they are often composed by thin beams and mobile parts that move in-plane over large distances. Their in-plane displacement is not the only important parameter, their buckling, out-of-plane parasitic displacement and vibrations need also to be characterized.

DHM® allows to track any moving element of the micro motor and to measure simultaneously its out-of-plane displacement in air, liquid, or vacuum, through glass window.

Description :

- Courtesy of : TU Chemnitz, Germany

- Material : Silicon

- Instrument : DHM R-1000, 1.25x magnification

- Time scale : live measurement @ 45fps

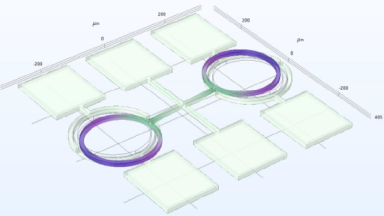

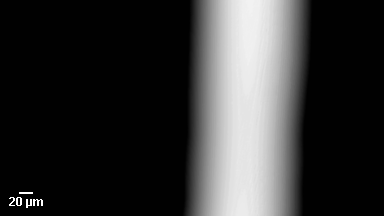

Micromotor under vacuum

DHM® systems are compatible with glass corrected objectives to ensure optimal optical quality measurement at both low and high magnification when measuring through a transparent window

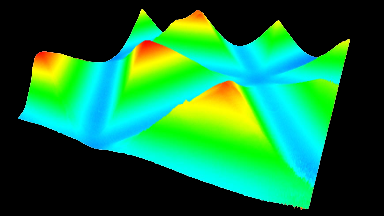

Thin structure – large displacement

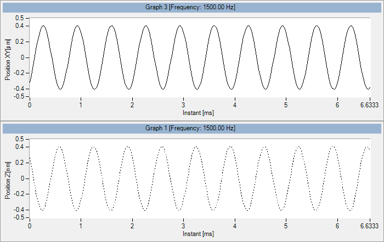

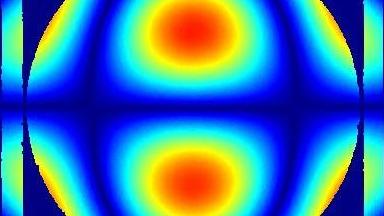

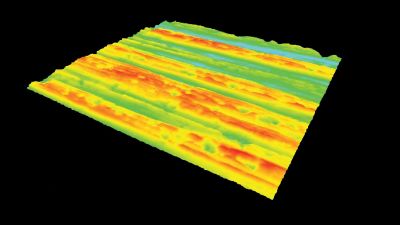

MEMSTool proprietary advance software algorithms enable to process DHM® 3D topography time sequence and to provide:

- Decomposition of displacements into in- and out-of plane components

- Dynamical analysis of buckling and vibrations

- Velocity and acceleration measurement

Get X-Y-Z displacement simultaneously

Accelerometer and gyroscope proof masses, vibrating wheels, or other sensing parts move generally both in- and out-of-plane, and often in vacuum.. Their characterization require both ultimate resolution and large measurement range.

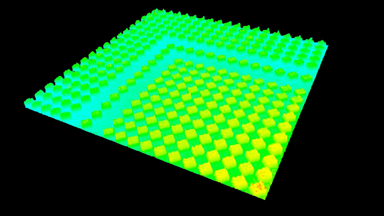

Track any moving element and measure simultaneously its out-of-plane displacement

DHM® acquire time-sequence of 3D topographies. This unique set of data combined with pattern tracking and edge detection algorithms provide reliable results in presence of :

- functional and sacrificial holes

- deposition and patterns

- non-flat surface

An unrivaled measurement range

From floor noise level to large displacement, the Holographic MEMS Analyzer provides :

- In-plane displacement from nanometers to millimeters

- Out-of-plane displacement from picometers to hundreds of micrometers