Time-Resolved Profilometer

Add the 4th dimension to 3D optical profilometry

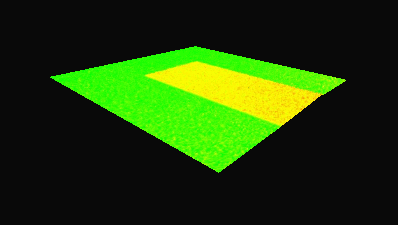

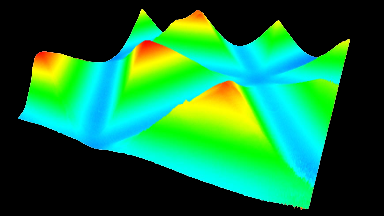

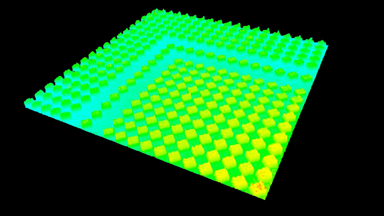

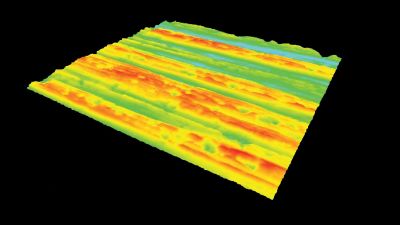

Time-resolved profilometer by Digital Holographic Microscopy (DHM®) provides 3D topography measurements of static samples with interferometric resolution. And additionally, thanks to its unique non-scanning technology, it provides ultra short time resolution, down to 10 μs. This unique 4D measurement ability opens a large and exciting new field of applications.

4D: time-sequence of 3D measurements

- 3D acquisition rate at 190 fps (100’000 fps optional)

- Temporal resolution down to 100 μs (10 μs optional)

- Large vertical measurement range, up to 200 μm

3D optical profilometer with interferometric resolution

- Sub-nanometer vertical resolution for any choice of objective

- High resolution and long working distance objective

- Measurement in air, in liquids, through optical window, within environmental chambers

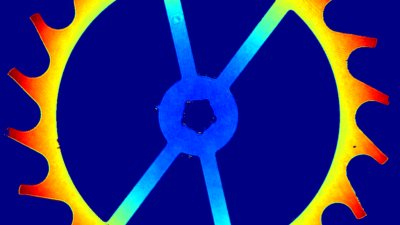

Characterization of sample changes due to:

- Thermodynamics parameters (pressure, temperature)

- Surrounding gas and liquid (deposition, corrosion)

- Mechanic and electromagnetic forces

- Light irradiance

User Testimonial

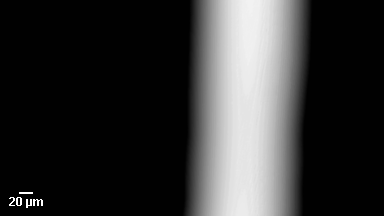

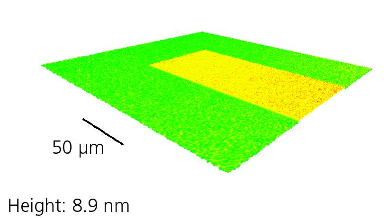

The researchers from the Netherlands presents a new concept to induce macroscopic morphing in polymer surfaces by an amplified response of a single molecule event. The kinetics of the surface deformation is measured by DHM Publications: 1. New insights into photoactivated volume generation boost surface morphing in liquid crystal coatings, Danquing Liu & Dirk J.Broer, Nature Communications 6, Article number: 8334 (2015),doi:10.1038/ncomms9334 2. Protruding organic surfaces triggered by in-plane electric fields, Danqing Liu, Nicholas B. Tito & Dirk J. Broer, Nature Communications 8, Article number: 1526 (2017), doi:10.1038/s41467-017-01448-w

We are making surface structures can be switched ‘on’ and ‘off’ by external means (at the frequency ranging from several Hertz to hundred Hertz. Digital Holographic Microscope (DHM) has the unique possibility to measure real-time 3D topography in a non-contact and non-scanning manner while keeps the vertical resolution to sub-nanometers

Live demo

System Configuration

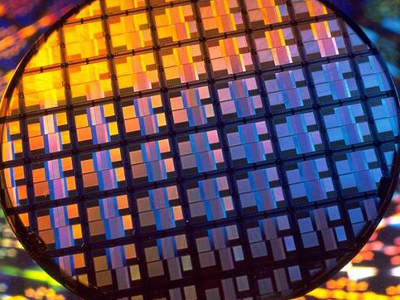

The Live 3D profilometer encompasses all the options to provide a complete environment for static and dynamical 3D characterization of your sample. The proposed solution responds to most of users characterization needs. However if you have special needs, Lyncée Tec is also pleased to provide you with turnkey customized solutions.

Sample stage

Manuel and motorized stages are compatible with each accessories. Motorized stages enable to extend the use of your system by adding automation and stitching functionalities. Samples holder enable to perfect positioning of your samples.

Vacuum and temperature control

Vacuum & thermal chambers enable change and control the samples surrounding of, e.g. vacuum, liquids, gas, high and low temperature, down to 196°C, up to 200°C, high pressure, etc. Measurements are as simple as in ambient conditions thanks to DHM® unique optical configuration.

Holographic Microscopes

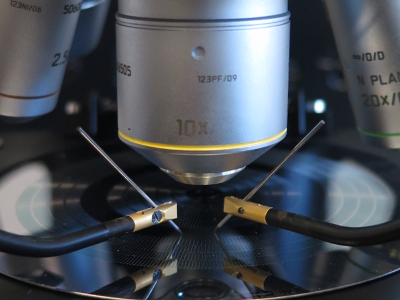

Reflection and transmission DHM® with one, two, and three wavelengths are fully compatible with the 4D configuration. Both can be configured with any objective, including long working distances, immersion, and glass corrected models, for measuring in presence of probes, in liquid, and through transparent covers respectively, always with optimal quality.

Camera

The standard camera supplied with the DHM® measures at 155 fps (full frame 1 Mpx). It is perfectly adapted for phenomena which occurs at a timescale down to tens of milliseconds. A 1000 fps (full frame 1 Mpx) camera is optional. It enables characterization of faster phenomena down to milliseconds timescale.

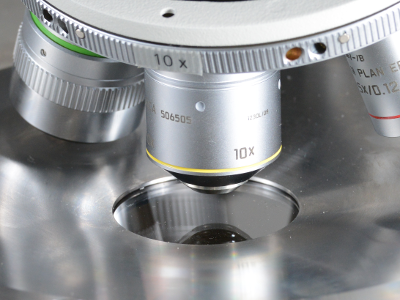

Objectives

Selection of a complete range of objectives to meet all your requirement. Besides standard objectives, DHM® can also configure with long working distance objective, glass corrected objective, oil/water immersion objectives, etc.

Sequence analysis software

Koala software has been designed for working with time sequence of measurements. Profile cut, vertical displacements, roughness and 3D representation are performed live. Post processing of sequences measurements enables tilt correction, re-focusing of measurements, and avi creations even longtime after their acquisition.

Competitive Strengths

| Features | DHM® | Scanning systems |

| Time-resolved measurements | ||

| Large areas, acc. to ISO standards, time to measure | [seconds] | [minutes] |

| Fast screening of a large amount of samples | ||

| Insensitive to vibration without anti-vibration system |

DHM® vs.White Light Interferometer (WLI)

Additionally to the advantages compared to any scanning method, DHM® has at least 2 key differences compared to WLI.

- The DHM® coherence length is 400 μm, while it is only 15 μm for WLI. Practically, this means that with DHM®, focalization is comparable to standard optical microscopy. On the contrary, with WLI, the user will need to search for fringes and tip-tilt the sample to position the surface to measure within this small range.

- DHM® is a more flexible instrument as it uses objectives from optical microscopy to measure through glass or in immersion. WLI requires specific interferometer objectives with limited and complex glass compensation.

| Features | DHM® | WLI |

| Time-resolved measurements | ||

| Sample set-up without need of tip-tilt sample | ||

| Large vertical visualization range for intuitive focalization | ||

| Measurement through glass with objectives from standard optical microscopy | ||

| Removable and flexible instrument head |

DHM® vs. Confocal Laser Scanning Microscope (CLSM)

Additionally to the advantages compared to any scanning method, DHM® has at least 2 key differences compared to CLSM.

- DHM® vertical resolution does not depend on the magnification, i.e. on the Numerical Aperture (NA), of the microscope objective. On the contrary, the vertical resolution of CLSM depends on the depth-of-focus, which decreases with the NA of the objective.

- DHM® vertical resolution is sub-nanometric, while the ultimate vertical resolution of CLSM achieved with high NA objectives is only of a few nanometers.

| Features | DHM® | Confocal Microscope |

| Time-resolved measurements | ||

| Large depth-of-focus for digital compensation of curvature | ||

| Removable and flexible instrument head |

DHM® vs. Contact Profilometer

Additionally to the advantages compared to any scanning method, DHM® is an optical profilometer and therefore a non-contact method, preventing from any damage. Measurement with contact profilometers, such as stylus profilometers and AFM, can be affected by artifacts due to elastic deformation of the surface, dirt dragged by the tips or by damaged tips.

| Features | DHM® | Contact profilometer |

| Time-resolved measurements | ||

| Fast screening of the surface to search for Region of Interest | ||

| Measurement through glass and in immersion | ||

| Non-contact, i.e. non-damaging method |

Specifications

| Measurement unit | Digital Holographic Microscope (DHM®) in Reflection or transmission configuration |

| Sample stage | XYZ manual or motorized stage |

| Software | Koala acquisition and analysis software |

| Acquisition time | Standard 100 μs (optional 10 μs) |

| Acquisition rate | Standard 190 fps (1024 x 1024 pixels) (optional up to 100’000 fps). Camera rate limited |

| Reconstruction rate | standard 60 fps (1024 x 1024 pixels hologram) |

| Vertical resolution | 0.2 nm |

| Vertical calibration | Determined by the wavelength, no mechanical movement calibration |

| Vertical measuring range (without any scanning) |

|

| Vertical measuring range in vertical scanning | Up to 1 mm, z-stage dependent |

| Lateral resolution | Objective dependent, down to 300 nm |

| Field of view | Objective dependent, up to 5 mm x 5 mm |

| Min. sample reflectivity | Less than 1% |

Lyncée Innovation Challenge 2016